Avez-vous besoin d’un nouvel équipement de traitement du lait dès que possible ? Ci-dessous, vous pouvez consulter la liste des articles en stock. Nous pouvons les expédier dans environ 1 à 2 semaines ouvrables (après réception d’un acompte). Le nombre d’appareils en stock est limité. Des modifications de l’équipement supplémentaire sur les appareils en stock sont possibles, et d’autres appareils sont également disponibles, alors envoyez une demande ! L’équipement des articles en stock peut varier. La liste est mise à jour mensuellement.

Pasteurisateur pour lait, yaourt… En savoir plus

P 50 EL PROFESSIONAL, La régulation de la vitesse du mélangeur, sortie DN50, contrôleur MC 500, sur un socle stable.

P 50 EL ADVANCED+,La régulation de la vitesse du mélangeur, sortie DN50, contrôleur MC 500, sur un socle stable.

P 100 EL ADVANCED+, La régulation de la vitesse du mélangeur, sortie DN50, contrôleur MC 500, sur un socle stable.

P 100 EL PROFESSIONAL, La régulation de la vitesse du mélangeur, sortie DN50, contrôleur MC 500, sur un socle stable.

P 200 EL ADVANCED+, La régulation de la vitesse du mélangeur, sortie DN50, contrôleur MC 500, sur un socle stable.

P 200 EL PROFESSIONAL, La régulation de la vitesse du mélangeur, sortie DN50 /65, contrôleur MC 500, sur un socle stable.

P 300 EL ADVANCED+,La régulation de la vitesse du mélangeur, sortie DN50 /65, contrôleur MC 500, sur un socle stable.

P 300 EL PROFESSIONAL,La régulation de la vitesse du mélangeur, sortie DN50 /65, contrôleur MC 500, sur un socle stable.

Caractéristique : refroidissement jusqu’à 4 ºC… En savoir plus

PH 100 EZ avec un mélangeur de base, DN65, contrôleur MC 500, sur roulettes.

Les cuves de fabrication de fromage sont utilisées pour le traitement thermique du lait en produits laitiers… En savoir plus

SKH 50 EL BASIC+, DN50, MC500, soutien stable

SKH 100 EL BASIC+, DN50, MC500, soutien stable

SKH 100 EL ADVANCED+, DN50, MC500, soutien stable

SKH 100 EL PROFESSIONAL, DN50, MC500, soutien stable

SKH 200 EL BASIC+, DN65, GPC145 / MC500, soutien stable

SKH 200 ADVANCED+, DN50, MC500, sur support sur roues /soutien stable

SKH 200 PROFESSIONAL, z Z mešalom, DN50, MC500, sur support stable

SKH 300 EL ADVANCED+, DN65, MC500, sur support stable

SKH 300 EW PROFESSIONAL, Z – Agitateur , DN65, MC500, sur support stable

SKH 300 EL BASIC+, DN50, MC500, sur support stable

SKH 500 EW PROFESSIONAL, DN65, MC500, sur support stable

SKH 500 EW PROFESSIONAL, DN65, MC500, Plate-forme de travail

SKM 50, DN40, Eliwell, sur support stable

SKM 150, DN50, Eliwell, sur support stable

La nouvelle gamme de produits Classic combine tous les éléments essentiels d’un pasteurisateur et d’une cuve de fabrication de fromage en un seul appareil. Elle inclut les fonctionnalités clés des deux appareils. Un appareil puissant à un prix abordable... En savoir plus

SK Classic 50 EL avt, mélangeur à hélice, sortie DN50, contrôleur MC350, sur un socle stable.

SK Classic 125 EL avt, mélangeur à hélice, sortie DN50, contrôleur Eliwell / MC350, sur un socle stable.

SK Classic 200 EL avt, harpe monobloc, sortie DN50, contrôleur MC350, sur un socle stable.

SK Classic 200 EW avt, harpe monobloc, sortie DN50, contrôleur MC350, sur un socle stable.

SK Classic 300 EW avt, harpe monobloc, sortie DN50, contrôleur MC350, sur un socle stable.

Lors de la commande d’un pasteurisateur ou d’une chaudière fromagère, vous pouvez commander une table de fromager sans frais de transport supplémentaires...

Les tables à fromage Plevnik SM 97, 147 et 199 sont équipées de pieds amovibles. Cela réduit les coûts de transport car elles peuvent être emballées avec le pasteurisateur.

P 200 + SM 97

MOS 50 z DN40 et étagère de rangement, sur roulettes

POS 50 z DN40 et étagère de rangement, sur roulettes

PRP-R 70 avec un support sur roulettes

PRP-R 120 avec un support sur roulettes

Presse à fromage pneumatique PPS-U2

Presse mécaniquea MS-U2

Pour recevoir la pâte de fromage, l’égouttage, le pré-pressage…

SM 97 avec étagère de rangement

SM 147 avec étagère de rangement

SM 199 avec étagère de rangement

SM 299 avec étagère de rangement

SOM 109 BASIC / ADVANCED avec étagère de rangement

SOM 159 ADVANCED avec étagère de rangement

SOM 209 ADVANCED avec étagère de rangement

PJ 13

PJ 25

PJ 50

PJ 100

PS 50 avec un support sur roulettes

PS 100 avec un support sur roulettes

RS 400 – VENDU

RS 300 – VENDU

KB 210, support sur roues

Armoire de fermentation OZF 700 et 1400 sont des unités de stockage thermiques (5 – 45 °C) utilisées pour les processus de fermentation… En savoir plus

OZF 700

OZF 1400

Après le pressage, les formes de fromage doivent être immergées dans une saumure pour saler le fromage… En savoir plus

OZS 700

OZS 1400

Nouveau type d’évaporateur permettant l’utilisation d’un réfrigérant écologique. Le corps de refroidissement soudé, de faible volume, nécessite une moindre quantité de réfrigérant et est plus facile à entretenir… En savoir plus

HM 302

HM 402

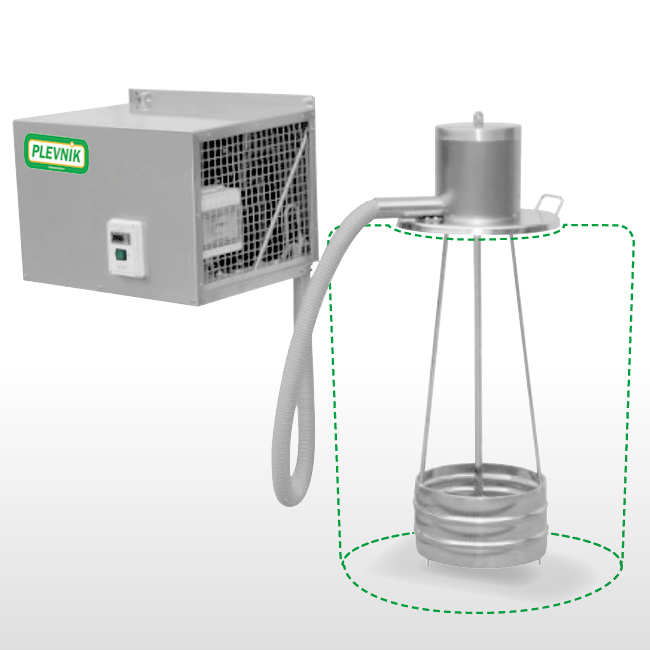

Les réservoirs de refroidissement de Plevnik sont indispensables à la production de lait de haute qualité et sûr du point de vue bactériologique… En savoir plus

HNP 100, DN 50, un socle stable

HNP 200, DN50, un socle stable

HNP 300, DN50, Dixell, un socle stable

Modèles perforés monoblocs Anelli (sans couvercle), pour fromages à pâte molle, semi-dure et dure, fromage blanc,…

Modèles perforés monoblocs (sans couvercle) d = 95 x h = 70 (P00678) – 300-400g

Modèles perforés monoblocs (sans couvercle) d = 115/120 x h = 135 (P29310) – 700-800g

Couverture P29310, d= 11,4 x h= 0,6

Modèles perforés monoblocs (sans couvercle) d = 140/145 x h = 140 (P00601) – 1k

Couverture za P00601 d= 14,4 x h= 0,8

Modèles perforés monoblocs (sans couvercle) d = 145/150 x h = 150 (P00602) – 1,4kg

Modèles perforés monoblocs (sans couvercle) d = 175/180 x h = 150 (P00605) – 2kg

Modèles perforés monoblocs (sans couvercle) d = 215/220 x h = 160 (P00607) – 3,5kg

Modèles perforés monoblocs (sans couvercle) d = 260/280 x h = 160 (P57330) – 6kg

Modèles perforés monoblocs (sans couvercle) d = 350/370 x h = 200 (P57340) – 15kg

Moules pour fromages à pâte semi-dure et dure. Adaptés pour la fabrication avec une presse.

Modèles micro-perforés en deux parties, FDA PE, d = 121 x 150 (MLI120PET4) – 1kg

Modèles micro-perforés en deux parties, FDA PE, d = 143 x 155 (MLI145PET45027) – 1 – 1,5kg

Modèles micro-perforés en deux parties, FDA PE, d = 194 x 170 (MLI192PEBT55025) – 2,5kg

Modèles micro-perforés en deux parties, FDA PE, d = 210 x 160 (MLI210PET4131) – 3kg

Modèles micro-perforés en deux parties, FDA PE, d = 248 x 200 (MLI250PPBT4) – 5kg

Modèles en trois parties avec grille pour fromages à pâte semi-dure et dure. Adaptés pour la fabrication avec une presse.

Modèle en trois parties avec grille, FDA PE , d=180×110 (C4410/Tomme), 1,8-2,2kg

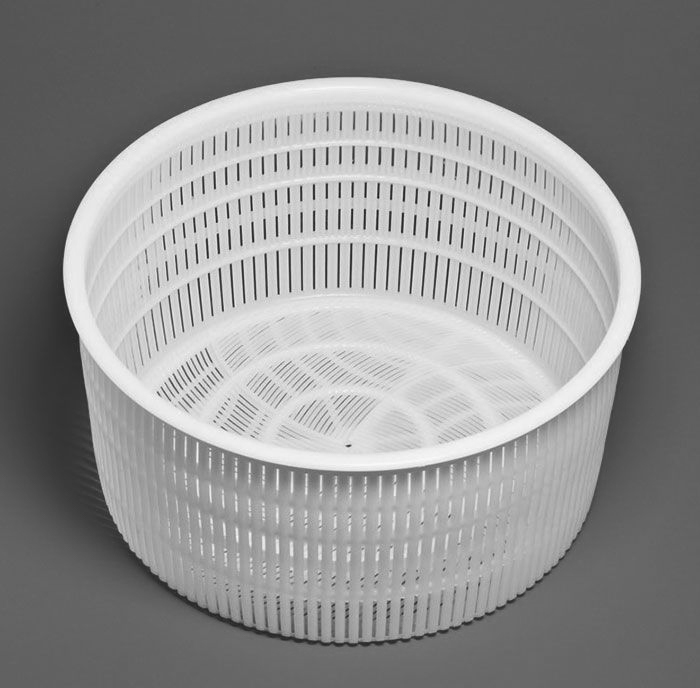

Panier pour le fromage blanc d = 120/200 x h = 105 (P00697) – 1,5kg

Cuillère pour la pâte de fromage d = 200, cca 3l

* Pour l’équipement en stock, des modifications peuvent être apportées aux équipements supplémentaires, et d’autres types sont également disponibles, donc veuillez demander une offre détaillée !

Écrivez-nous et nous serons heureux de répondre à toutes vos questions.

Ajouter de la valeur au lait.

PLEVNIK

Ingénierie et production, d.o.o.

Podsmreka 56,

1356 Dobrova, Slovenija

Téléphone: +386 1 200 60 80

2020 © Plevnik, d.o.o., Tous droits réservés.